Highly resilient and recyclable UD tapes made from stereocomplex PLA

High-performance technical fibers are used in various applications, but they are often made from fossil raw materials and are not biodegradable. This is where the "scPLA-UD-Tape" project of the Fraunhofer Cluster of Excellence Circular Plastics Economy CCPE comes in, with the aim of creating intrinsically reinforced materials for lightweight construction that are highly resilient, biodegradable and significantly easier to recycle.

High-performance technical fibers can be found in seat belts, breathable clothing, particularly stable concrete structures and medical implants. In fiber-reinforced plastics, they ensure highly durable and lightweight components, for example for the automotive industry. Tons of such fibres are produced in Germany every year, often from plastics such as polyester (PET) and polyamide (PA), which are made from fossil raw materials and are not biodegradable.

Polylactic acid (PLA) is an attractive candidate in the search for more environmentally friendly alternatives. This biopolymer, which is often made from corn or sugar beet, is becoming increasingly widespread in many fields of application. However, PLA does not yet have a sufficient thermo-mechanical profile to be used as a raw material for reinforcing fibers and cannot match the performance of PET and PA.

In previous research activities, the Fraunhofer Institute for Applied Polymer Research IAP has succeeded in advancing the production process of high-quality stereocomplex PLA (scPLA) filament yarns to such an extent that thermally resilient scPLA yarns can be produced with a mechanical property profile that comes very close to that of technical PET fibers. Two types of PLA are combined to produce scPLA, resulting in crystal structures that allow the melting temperature to rise by up to 60 Kelvin. In cooperation between the Fraunhofer IAP and the Fraunhofer Institute for Chemical Technology ICT, it was also demonstrated that scPLA filament yarns can act as reinforcing fibers in PLA-based organic sheets and offer decisive advantages for recycling. "Because the matrix and fibers are made from the same material, a single-component composite material is created that no longer requires complex separation steps. Lightweight materials and components can thus be better recycled and make an additional contribution to sustainability," explains Dr. Evgueni Tarkhanov, head of the development of scPLA fibers at the Fraunhofer IAP.

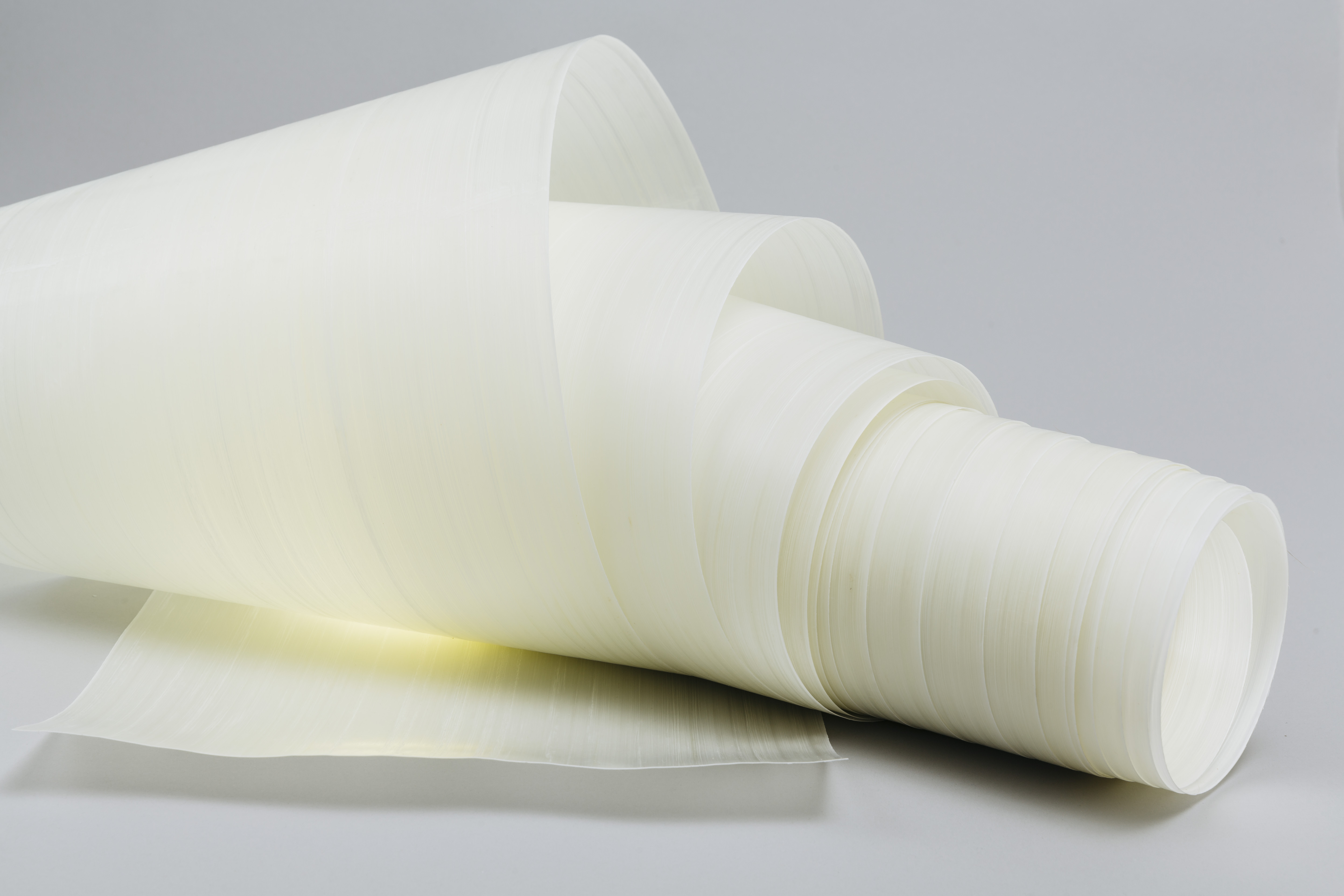

"We want to use these improved properties of scPLA fibers in a UD tape as a continuous fiber-reinforced semi-finished product for self-reinforcement. This will enable us to achieve material properties that are suitable for a wide range of applications and significantly increase the maturity of this technology," says Ivonne Jahn, who is leading the project at the Fraunhofer Institute for Microstructure of Materials and Systems IMWS. UD tapes are thin thermoplastic layers with a thickness of 200-300 µm and a very high fiber content. The reinforcing fibers are aligned unidirectionally. As a result, they can be placed on top of each other in a load-oriented and precisely fitting manner during further processing, which takes place in a very efficient melt impregnation process. This offers enormous potential for lightweight construction. As a semi-finished product, the UD tape is intended to prevent fiber undulations (a curvature of the fiber that can lead to reduced strength and stiffness of the material) and increase the fiber content in the material. As a local reinforcement in components, the use of UD tapes is also significantly more material-saving and therefore more resource-efficient than, for example, the use of fabric-based organic sheets as a reinforcement component, which, always available as a large semi-finished product, result in more waste when fitting into the component geometry.