Videos

Here you can see a selection of our videos. You can find the entire video collection here.

Here you can see a selection of our videos. You can find the entire video collection here.

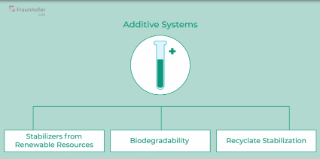

Additive systems for recycled material

As experts in plastic additives, Fraunhofer CCPE develops tailor-made products right up to commercial use. In collaboration with our project partner L. Brüggemann GmbH & Co. KG, our additive systems improve recycled material up to virgin material properties.

After a brief analysis of the existing product, the R-strategies (Reduce, Reuse, Recycle, Refuse, Rethink, Repair, Refurbish, Remanufacture, Repurpose and Recover) are analyzed for a scenario, for example saving CO2 or primary raw materials. The simulation results show which ecological and economic short- and long-term effects can be expected from a changed product design, and the appropriate innovation path can be derived from this.

How can products and product systems be made more circular? Which fields of action play a role here? How can this be tested? Fraunhofer CCPE researchers developed the Self-Check Tool Circular Readiness Level® (CRL) precisely for these questions. The CRL® is a web-based tool for self-validation, with which companies can assess the maturity of products or product systems in terms of the Circular Economy. It tests to what extent a product already addresses the strategies of the Circular Economy in the fields of product design, product service system, end-of-life management and closed-loop recycling and where there is still potential for improvement. The Self-check is aimed at all actors along the life cycle of products and available online as a tool for companies to validate themselves: https://ccpe.iml.fraunhofer.de/selfcheck/

Fraunhofer CCPE is researching into new additive systems with the aim of biostabilization, biodegradability and recyclate stabilization. By adding such additives, the properties of plastics can be tailor-made and improved with regard to their sustainability.

At Fraunhofer CCPE, researchers are investigating the manufacturing process of thermally stable biopolyester fibers that facilitate the recycling of fiber composites.

Old Face masks can be recycled into materials, which in turn can be used to make new masks. This is how the iCycle® process works. The thermochemical process for material separation was developed at Fraunhofer UMSICHT in Sulzbach-Rosenberg. Plastics and other organic components are thermally decomposed in an oxygen-free atmosphere. In this way, not only are contained metals or fibers gently exposed, but also high calorific value energy sources in the form of oil and gas are obtained. The colleagues explain exactly how this works in the video. More information about the face mask recycling technology iCycle®: https://www.umsicht-suro.fraunhofer.de/en/Our_Solution/iCycle.html

Plastic is currently the subject of much discussion in our society. Yet plastic is light, stable, inexpensive and versatile, and has become an important part of our everyday lives. The solution: a circular economy for plastics. Here's how it could work.