System mapping: Which strategy is best in the circular economy?

Can we achieve our sustainability goals with recycling? What other strategies are there in the circular economy and how do they differ in terms of their long-term effects? What role do market dynamics play and how do the processes influence each other? Companies will inevitably encounter such questions at some point in the transformation to a circular economy.

In order to remain competitive and sustainable in the long term, many companies need to address these issues and adapt their business models accordingly. The Fraunhofer Cluster of Excellence Circular Plastics Economy CCPE is developing advanced solutions with simulation-based tools.

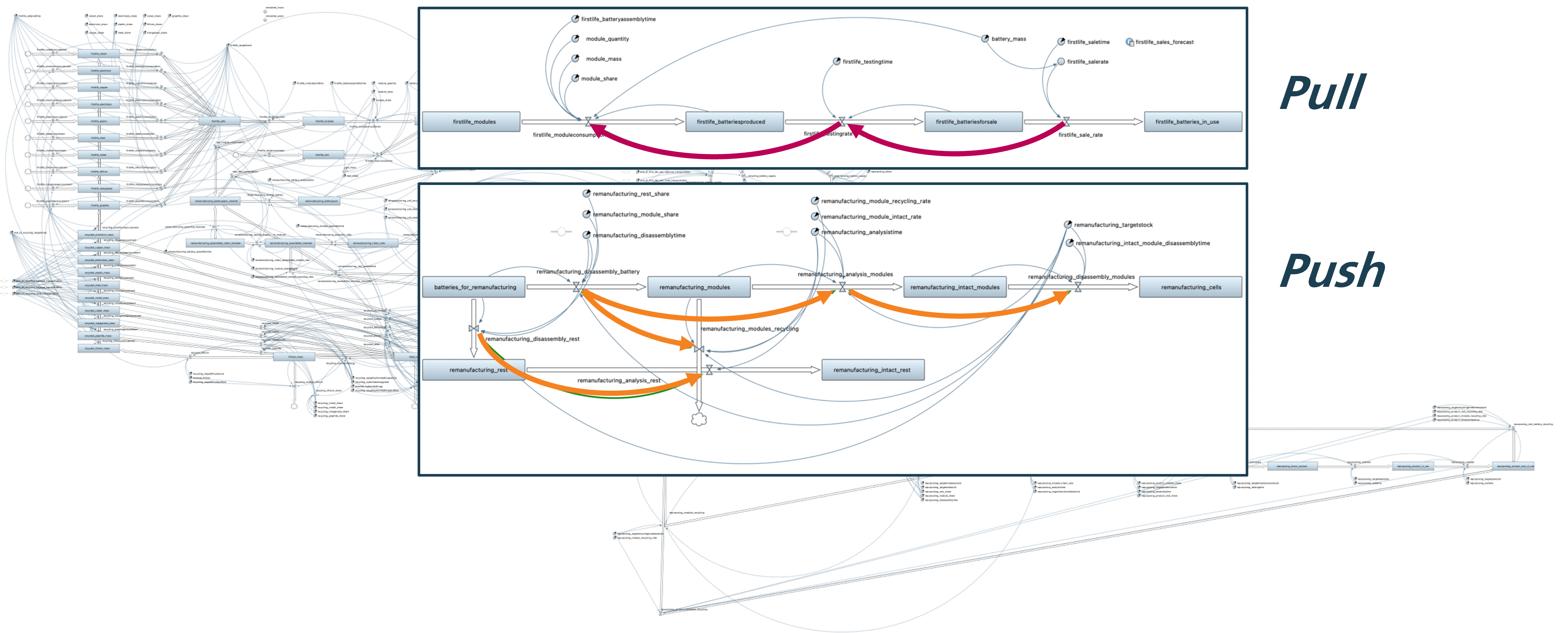

To this end, well-known tools such as system dynamics or agent-based simulation are combined with proven life cycle assessment approaches. At the centre of the simulation model is either a completely new product, such as a traction battery, or a long-standing product that is to be redesigned in the sense of a circular economy. By simulating the interplay of current sales figures, future demand and the processes of the value chains, the effects of different design scenarios and recycling routes on the CO2 footprint as well as on the costs and revenues of the overall system can be analysed. In addition to the comparison of company-specific scenarios, it can also be analysed whether recyclate quotas agreed by the EU can be achieved with existing technologies or whether higher-value use at component rather than material level is in conflict with these quotas. Such higher-value strategies for traction batteries that have already been modelled are, for example, ‘remanufacturing’ for reuse in cars or ‘repurposing’ in an alternative application such as a stationary battery storage system.